More Top Stories

Solar power battery repairs ‘could take up to 12 months’

15 April 2024

Police shortage leads to drop in checkpoints

9 April 2024

Sarakura declared new Penrhyn MP

16 March 2024

Govt says $1.3m invested in Lady Samoa charter

22 February 2024

Mass milkfish die-off in Penrhyn raises concerns

3 April 2024

Regulator defends Starlink users

9 April 2024

Aitutaki’s heritage preserved in new anthology

4 January 2024

Avatiu Eels retain Nines title

8 January 2024

Beddoes crowned top athlete

8 January 2024

NRL player Dargan dies in Aitutaki motorcycle crash

24 December 2023

‘Please heed the signs’: resident makes plea to tourists

20 December 2023

Cook Islands set to play in new World Series

10 October 2023

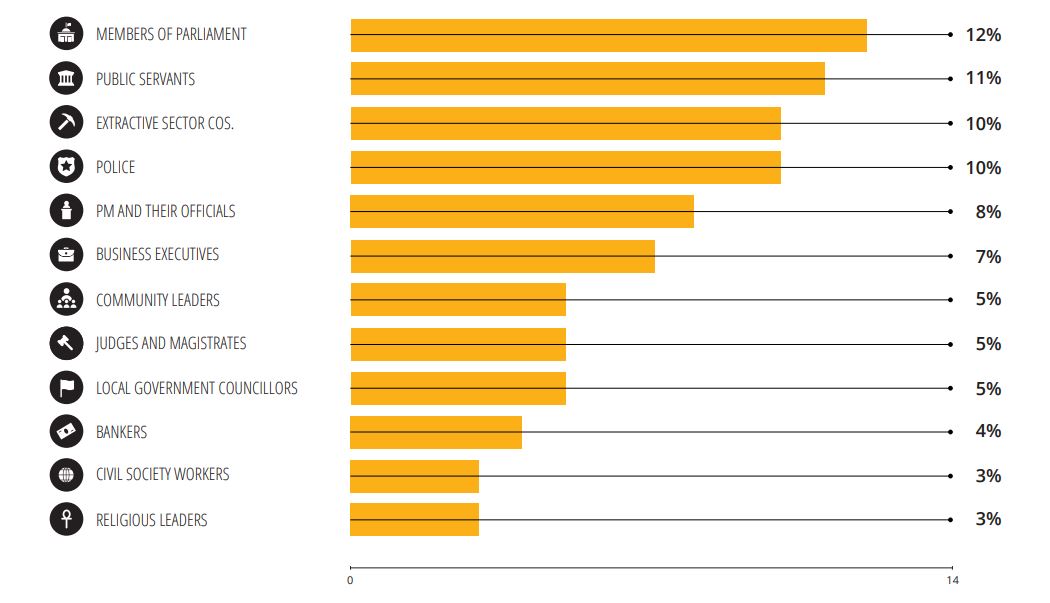

Corruption report exposes ‘bribe and sexual favours’

17 January 2023

Corruption in the Cook Islands?

21 January 2023

Moana target 2025 World Cup

11 November 2022

Chlorine safe and effective if dose is right, says expert

Thursday 15 August 2019 | Written by Rashneel Kumar | Published in Health

Share

India-based John Koruthu shares his chlorine experience in Rarotonga in the 1980s. 19081418

Chlorine can be an efficient water disinfection in Rarotonga, says a food technologist.

Chlorine can be an efficient water disinfection in Rarotonga, says a food technologist.

To continue reading this article and to support our journalism

CLICK HERE TO SUBSCRIBE NOW

for as little as $11 per month.

- Up to date and breaking news

- Includes access to Premium content

- Videos and online classifieds

Already a subscriber, click here